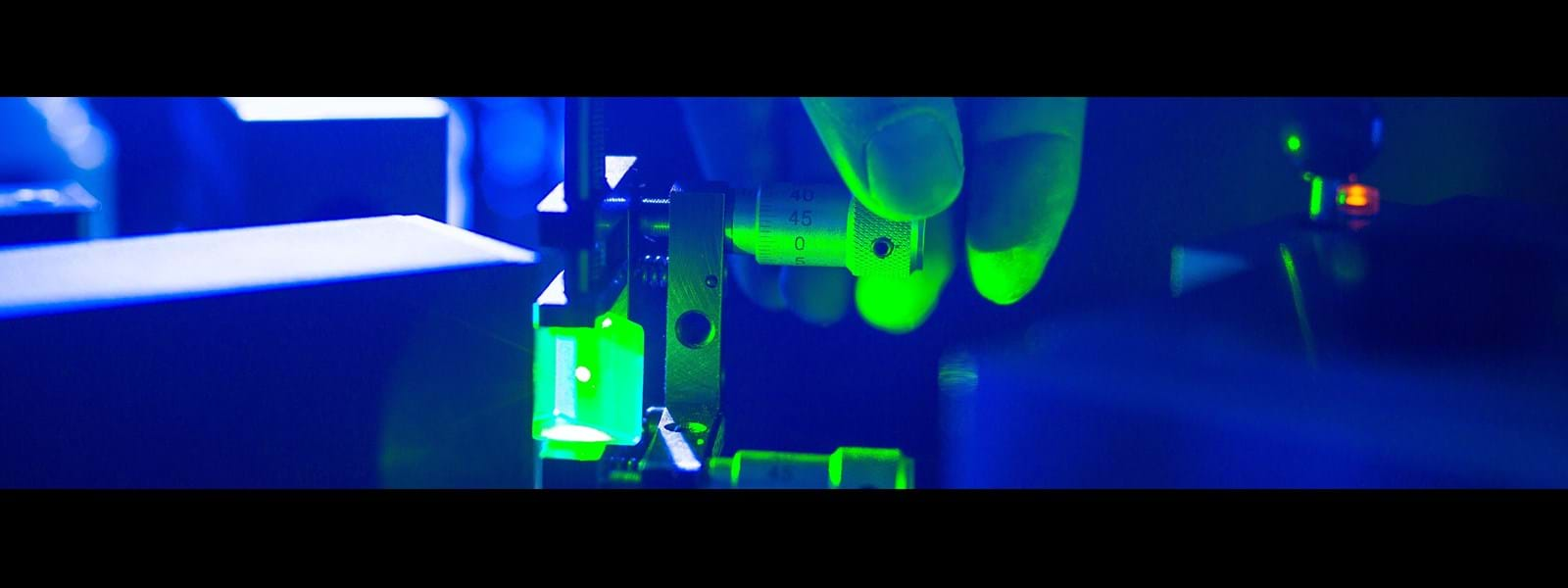

Optical Characterization and Metrology

Our optical characterization and measurement services deliver accurate, fast, and confidential results to validate your optical components, coatings, or systems. INO’s metrology laboratories and experts are at your disposal to enhance product reliability and shorten your development cycles.

Validate the optical performance of your components, systems, and materials with high-precision measurements. Gain speed, reliability, and confidence to make decisions and deliver faster.

- Surface accuracy, optical alignment, and image quality

- Spectral performance from UV to IR (transmission, reflection, or emission)

- Photometry, radiometry, and colorimetry

- ISO 9001 certification

- Calibrated optical measurement instruments.

INO offers comprehensive optical characterization and metrology services. Our experts deliver precise, fast, and actionable results to help you improve your designs and verify product compliance.

Optical characterization involves determining the physical or functional properties of a material, component, or system, while metrology focuses on accurately measuring geometric or physical quantities. In both cases, the properties of light are used to obtain reliable information.

Features

Reliability and Compliance

Informed Decisions

R&D Flexibility

When to Contact Us

- Prototype validation

- Supplier verification

- Optical design optimization

- Performance diagnostics

Measurements Tailored to Your Industry

Medical Devices

Aerospace

Defence

Telecommunications

Energy

Advanced Manufacturing

Our Measurement Capabilities

Spectral Characterization

Measurement of the light reflected, transmitted, or absorbed by a material or component as a function of wavelength (UV, visible, IR).

- Equipment: Spectrophotometers, spectroradiometers.

- Materials: Glass, plastics, metals, wood, fabrics, optical thin films, and other coatings.

- Deliverables: Spectral curves, data tables, and interpretation.

Optical Surface Metrology

Interferometric measurements of flatness, curvature, and irregularity to determine the precision of flat or spherical surfaces.

- Equipment: Laser interferometers.

- Materials: Lenses, mirrors, windows, and optical prisms.

- Deliverables: Interferograms, data tables, and interpretation.

Light Source Characterization

Measurements of intensity, illuminance, luminance, and emission spectrum.

- Equipment: Photometers, fibre-optic spectrometers, spectroradiometers.

- Materials: LEDs, lamps, lasers.

- Deliverables: Spectral or spatial curves, data tables, and interpretation.

Imaging System Performance

Measurement of transmitted wavefront quality, contrast, and image resolution.

- Equipment: Laser interferometers, wavefront analyzers, MTF analysis systems.

- Materials: Lenses and camera objectives.

- Deliverables: Interferograms, contrast (MTF) curves, data tables, and interpretation.

Other Services

Colorimetry, lens centering, and alignment of custom optical systems.

Measurement Capabilities and Key Parameters

| Capability | Description | Typical Range | Deliverables |

| Spectrometry (Materials) | Transmission or reflection spectrum of a material to assess optical performance and losses. | 200-2500 nm, 2-300 µm |

Spectral curves |

| Spectrometry (Light Sources) | Emission spectrum of a light source to characterize the distribution of emitted energy. | 350-1000 nm | Spectral curves |

| Photometry / Radiometry | Measurement of illuminance, luminous intensity, or luminance visible to the human eye, or equivalent radiometric energy in the UV or IR ranges. | 380-780 nm (visible), 350-2500 nm (UV, IR) |

Tables, spatial curves |

| Interferometry | Precision measurement of an optical surface in terms of flatness, curvature, and irregularity compared with design specifications. | 633 nm = 1 lambda = 1 wave = 2 fringes | Interferograms (3D surface map), Power, PV, and RMS values |

| Wavefront Analysis | Measurement of the error induced on the transmitted or reflected wavefront by an optical component or system | 633 nm = 1 lambda = 1 wave = 2 fringes | Interferograms (3D wavefront map), PV and RMS values |

| Image Analysis | Measurement of contrast, resolution, and distortion of the image produced by a lens or other optical system. | n/a | MTF curves, distortion curves |

| Colorimetry | Measurement of colour as perceived by the human eye using coordinates in a tristimulus colour space. | 380-780 nm | CIE xyY, Lab*, or other values |

| Centering and Alignment | Optimization of the assembly of optical components forming a custom-designed lens or telescope. | n/a | Precision in microns |

How It Works

Defining Your Needs

Protocol Development

Measurement

Analysis and Validation

Report and Recommendations

Why Choose INO

- Over 35 years of expertise in applied photonics

- ISO 9001 certification

- Specialized laboratories and calibrated instruments

- Ability to tailor protocols to your specific needs

- Opportunity for R&D collaboration on custom innovations

Frequently asked questions

What is optical characterization?

It refers to a set of methods that use the properties of light to determine and quantify the optical behaviour of a material, component, or system.

What types of samples can you measure?

Lenses, mirrors, filters, windows, and other optical components; fibres, sensors, objectives, lasers, light sources, thin films, and optoelectronic modules; as well as a wide range of material samples such as glass, plastic, metal, minerals, wood, and fabric.

What are the typical turnaround times?

Between 3 and 10 business days, depending on the complexity and number of samples.

What type of deliverables do you provide?

You'll typically receive your results as an Excel file or image set by email. Upon request, we can also provide a detailed report with data, charts, and recommendations.